Raise boring is a drilling technique used to create shafts in hydropower, infrastructure & tunnel / mining industry, where you first drill a smaller hole (pilot drilling) between two existing levels, and then we mount a reamer down at the breaktrough site, after that you pull the reamer up through the rock to create the shaft.

If you are interested and want more information regarding raise boring, you are welcome to contact us.

Below you can see the different drill rigs and their specifications.

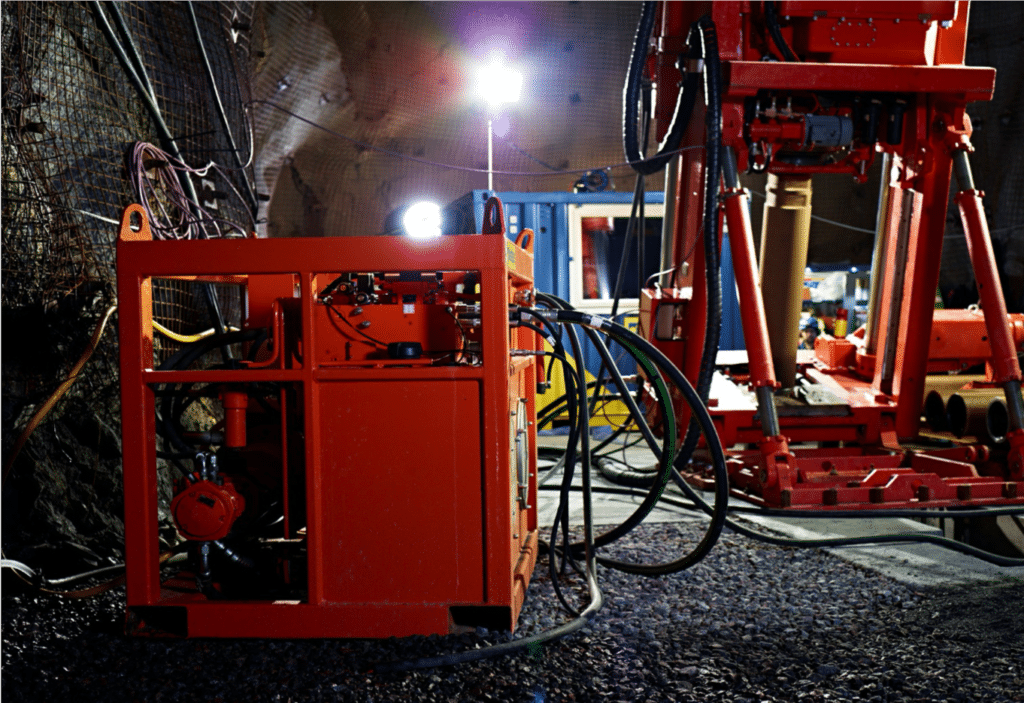

Our raise boring rigs

Epiroc Robbins 123 RH

- Year: 2018

- Raise diameter: ∅0,35 – ∅6,5 meter

- Raise length: Up to 1 100 meter

- Reaming torque: 540kNm

- Reaming thrust: 8 923 kN

- Power requirement: 706 kVA, 400 V, 50Hz

- Weight of rig incl. pipeloader: 32 000 kg

- Crawler: Yes

TRB Rhino 2000

- Year: 2016

- Raise diameter: ∅0,35 – ∅5,5 meter

- Raise length: Up to 800 meter

- Reaming torque: 460 kNm

- Reaming thrust: 6 800 kN

- Power requirement: 600kVA, 400 V, 50Hz

- Weight of rig incl. pipeloader: 24 100 kg

- Crawler: Yes

TRB Rhino 2000

- Year: 2015

- Raise diameter: ∅0,35 – ∅5,5 meter

- Raise length: Up to 800 meter

- Reaming torque: 460 kNm

- Reaming thrust: 6 800 kN

- Power requirement: 600kVA, 400 V, 50Hz

- Weight of rig incl. pipeloader: 24 100 kg

- Crawler: Yes

TRB Rhino 400

- Year: 2004

- Raise diameter: ∅0,25 – ∅1,8 meter

- Raise length: Up to 400 meter

- Reaming torque: 85 kNm

- Reaming thrust: 2 010 kN

- Power requirement: 160 kVA, 400 V, 50Hz

- Weight of rig incl. pipeloader: 9 200 kg

- Crawler: No, lifted with wheel loader or excavator